In a continuation of my recap from Day 1 the 2nd day

of the Northeast Lean Conference Leveraging Lean to Thrive in Uncertain Times

did not disappoint. Andrea Haas, President at Summit Polymers, demonstrated how

they used Lean Practices to Succeed in automotive industry after Tariffs, COVID

labor shortages, microchip shortages, global supply chain disruptions, and inflation.

They specifically focused on Jidoka, building in quality with Poka Yoke and Andon,

standardized work, and kaizen to successfully navigate these uncertain times.

Cultivating a Lean Culture Through Individual Change

Management

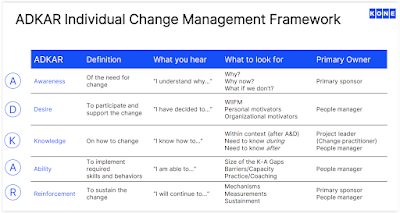

Evan McCoy, Continuous Improvement Leader at Kone, shared

how to create awareness, desire, knowledge, action, and results around creating

a Culture of Continuous Improvement. What can we do about the fact the 70% of

change initiatives fail?

He promotes the ADKAR Framework for Change

Awareness – change begins with understanding why

Employees will want to know why? Why now? What’s Wrong?

Leaders must be ready to answer what’s changes and why,

risks of not changing, what’s not changing, why now

Desire – Change involves personal decisions

Build desire and momentum by showing not telling. Focus on

the small improvements. Celebrate and show recognition.

Knowledge – Change requires knowing how

Do and show rather than tell and teach. Formal training

(10%), learning through experience (70%), learning through socialization (20%)

Ability – Change requires action in the right

direction

People leaders must set the tone for the teams. Time is

constrained resource create space and culture for improvement. Allow for

experimentation and risk. Improvements must be visible and impactful.

Reinforcement – Chage must be reinforced to be

sustained

Meaningful link between improvement and daily work. Simpler,

easier, more efficient improvement in process. Accountability systems to

reinforce. Performance measures that connect and reward and recognize by

leadership and peers.

Breaking the Buy-In Barrier: Getting Lasting Senior

Leadership Commitment

Melissa Lin, Associate Director Continuous Improvement at

Phillips, knows about the importance of senior leadership buy-in. To be

successful you need senior leadership commitment actively and visibly

participating throughout the journey, building a coalition of peers, and

communicating with employees.

Is the resistance directed at you or because of you or

something else?

These are the most common obstacles to senior leadership

buy-in, what they really mean, and how to overcome them.

Gimme the ROI – They want the facts, data,

quantifiable benefits and/or risk mitigation to buy-in so you can solve that

with a strong, clean A3.

I don’t

see the problem – They want the facts verified with their own eyes,

irrefutable evidence change is required to be convinced so bring them to the

Gemba and let the problems show themselves or bring it to them in the form of

spaghetti diagrams or VSMs.

This isn’t

a priority for us – They want to see connection to the big picture, need

help focusing on top priorities and fixing problems on their plate so use

Hoshin Kanri to connect to True North and use Root Cause & 5 Whys to solve

problems.

I don’t

think it’ll work

– They want results, proof of improvements, and one less thing to worry about

so have well scoped value stream for kaizen and show respect for people.

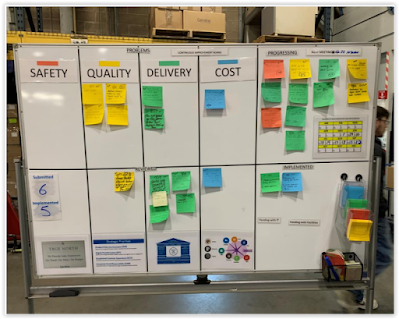

Developing a Company of Problem Solvers

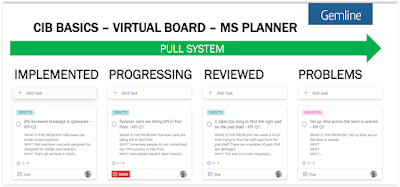

Edge Coble, Director of Continuous Improvement at Gemline, shared

how they use Continuous Improvement Boards to develop, engage, and empower

everyone into problem solvers. Continuous improvement is about seeing the

problem not waste elimination. Waste is a byproduct of poor flow.

The CI Board is:

Way to

identify and resolve problems

Aligned

to corporate goals & dept KPIs

Diversity

of viewpoints, knowledge & experience

Cross-pollination

& rapid deployment of improvements

Source

of accomplishment and pride

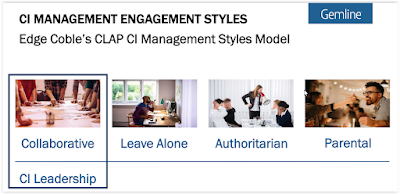

The CI Management Model for Engagement has these leadership styles

Collaborative – CI Leadership – working

together

Leave Alone – Manager not around

Authoritarian – Tell what to do

Parental – Treat as part of

extended family

Continuous improvement is about spotting the disruptions in

your team’s workflow, understanding why it’s happening, and determining a speedy

correction.

Created an idea board in MS Planner (Teams) – see picture

Passing the Baton to a New Generation of Problem Solvers

Karl Wadensten, President of Vibco, was the final keynote of

the conference. As Vibco celebrates its 52nd anniversary, Karl shared how

embracing Lean has powered his company through challenging times and still

enables them to thrive today. I’ve been to their facility several times and it

is very impressive so I would recommend a visit.

The future of continuous improvement will be characterized

by a more balanced approach that prioritizes job satisfaction, social

responsibility, and sustainable practices alongside traditional metrics of

success. Organizations that embrace this paradigm will not only enhance

employee engagement and satisfaction but will also contribute positively to

society an the environment.

Gen Z has a distinctive perspective on the current

workplace, influenced by their upbringing, and educational experiences which is

different than other generations.

Emphasis on purpose – seeks work

that aligns with their personal values and contributes positively to society.

Focus on learning and growth

Importance of mental health

Comfort with Technology

Preference for collaborative Work

Skepticism Towards traditional

career paths

Job satisfaction over job security

Understanding these perspectives allow organizations to

create environments that attract and retain Gen Z talent.

When the rubber hits the road. The boss is the coach. The

boss is authentic. The boss shows vulnerability. The boss knows when to lead

and when to follow. The boss show’s purpose and passion for his people.

The 21st Annual Northeast Lean Conference will be October 27 & 28, 2025 at the Double Tree Hotel & Conference Center in Manchester, NH.